Because the worldwide group gathers to debate Ukraine’s post-war restoration, a brand new evaluation led by the College of Oxford demonstrates that inexperienced metal must be prime of the agenda.

Rebuilding Ukraine’s ravaged metal sector—as soon as hostilities stop—presents a golden alternative to harness the placing financial advantages of low emissions metal manufacturing, in accordance with researchers on the College of Oxford.

In a brand new report, “Techno-economic optimization of steel supply chains in the clean energy transition: A case study of post-war Ukraine,” printed within the Journal of Cleaner Manufacturing, they display that rebuilding Ukraine’s metal sector to have close to zero emissions would generate $164 billion value of further GVA in comparison with a pathway based mostly on conventional coal-based steelmaking.

Moreover, a strong inexperienced metal sector in Ukraine would have ripple results throughout your entire economic system, as an example via stronger provide chain hyperlinks. As an example, changing coal as the primary heating supply in metal furnaces with renewable power would radically shift the middle of gravity of Ukraine’s metal trade from jap areas in the direction of western and southern areas, and speed up financial development.

Metal is a significant factor of Ukraine’s economic system. Earlier than the battle, Ukraine was the 14th largest international metal producer with 21.4 million metric tons of crude metal output in 2021. However its pre-war metal trade was additionally one of many dirtiest on the planet. In 2020, the Ukrainian metal trade was answerable for 48 Mt CO2: 15% of the nation’s complete CO2 emissions. If Ukraine had been to affix the EU, nevertheless, it might change into topic to “The EU Green Deal” goal for close to zero-emission metal by 2030.

Within the new research, the researchers be aware that Ukraine has the clear potential to develop the clear power infrastructure wanted for a full inexperienced metal transition– together with a strong provide of renewable power, and inexperienced hydrogen produced utilizing renewable power.

Ukraine additionally sits on huge reserves of iron ore—the primary uncooked materials wanted to make metal utilizing virgin supplies—and is effectively positioned for entry to European prospects.

However efficiently redeveloping Ukraine’s metal sector would require entry to capital, clear local weather insurance policies, and powerful regional commerce hyperlinks.

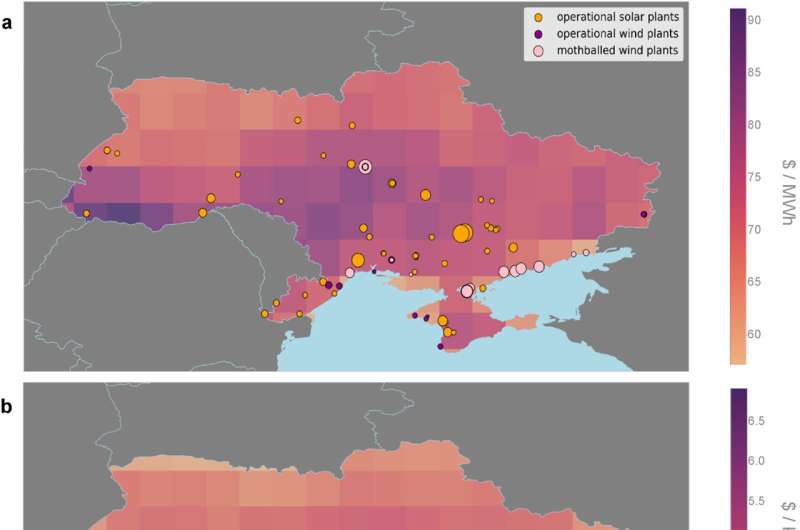

The researchers suggest that new inexperienced metal mills can be located in shut proximity to westward cross-border railway crossings and southbound Black Sea ports, in addition to optimum photo voltaic and wind power sources.

This may considerably enhance demand for land and sea transport providers, re-routing them in the direction of Western/EU markets, and likewise create new demand for the manufacturing of inexperienced hydrogen and inexperienced ammonia for fossil-free fuels.

In accordance with the report, a full metal manufacturing restoration in Ukraine would require funding of $62 billion over 20 years: $45.9 billion for renewable power infrastructure, $6.6 billion for power storage, and $9.5 billion for iron and steelmaking furnaces. Nevertheless, this funding would have wider results: in 2021, for each $1 invested in Ukraine’s primary metals trade, a further $3.28 was generated elsewhere within the economic system.

The World Financial institution estimates that Ukraine’s full post-war restoration and reconstruction wants would require $486 billion. Thus, by comparability, Ukraine’s inexperienced metal funding wants quantity to six% of the nation’s complete post-war reconstruction wants over the primary 10-year interval.

As a constructive step ahead, a latest dedication by home gamers (together with giant Ukrainian steelmakers Metinvest and ArcelorMittal) of $35bn into the medium-term inexperienced metal transition technique till 2035 means the excellent quantity wanted can be considerably decrease (Metinvest, 2023).

Finally, Ukraine may present a really perfect blueprint for an urgently-needed international transition in the direction of low-emission metal manufacturing. Globally, steelmaking produces extra CO2 than another manufacturing and development trade, comprising round 8% of complete international emissions—2.8 gigatons of CO2 per 12 months. As compared, worldwide aviation transport accounts for two.5% of world CO2 emissions.

With potential worldwide donors and personal buyers gathering in Berlin on 11–12 June for the Ukraine Restoration Convention 2024—a high-level annual political occasion that goals to mobilize worldwide help for Ukraine- the researchers hope that inexperienced metal will likely be excessive on the agenda.

Extra data:

Alexandra Devlin et al, Techno-economic optimisation of metal provide chains within the clear power transition: a case research of post-war Ukraine, Journal of Cleaner Manufacturing (2024). DOI: 10.1016/j.jclepro.2024.142675

College of Oxford

Quotation:

A inexperienced metal pathway would turbocharge Ukraine’s post-war restoration, research finds (2024, June 11)

retrieved 11 June 2024

from https://techxplore.com/information/2024-06-green-steel-pathway-turbocharge-ukraine.html

This doc is topic to copyright. Other than any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.