In recent times, engineers and scientists worldwide have been engaged on new applied sciences for producing electrical energy from renewable vitality sources, together with photovoltaics (PVs), wind generators and hydro-power mills. Another answer for mitigating the impression of local weather change could possibly be to transform the surplus or waste warmth generated by industries, households and sizzling pure environments into electrical energy.

This method, generally known as thermoelectric energy era, depends on the usage of supplies with invaluable thermoelectric properties. Particularly, when these supplies are uncovered to notably excessive temperatures on one aspect and colder ones on the opposite, electrons inside them begin to circulation from the recent aspect to the cooler one, which generates electrical potential

Whereas latest works have recognized some promising thermoelectric supplies, the module efficiency is unsatisfactory because of the challenges related to designing and fabricating optimum module buildings. This considerably limits their potential real-world integration in thermoelectric modules.

Researchers at Pohang College of Science and Expertise, the George Washington College and different institutes just lately launched a brand new technique for designing thermoelectric supplies primarily based on copper selenide (Cu2Se).

This technique, outlined in a paper revealed in Nature Vitality, allowed them to design promising supplies for high-power era utilizing strategies that could possibly be simpler to breed on a big scale.

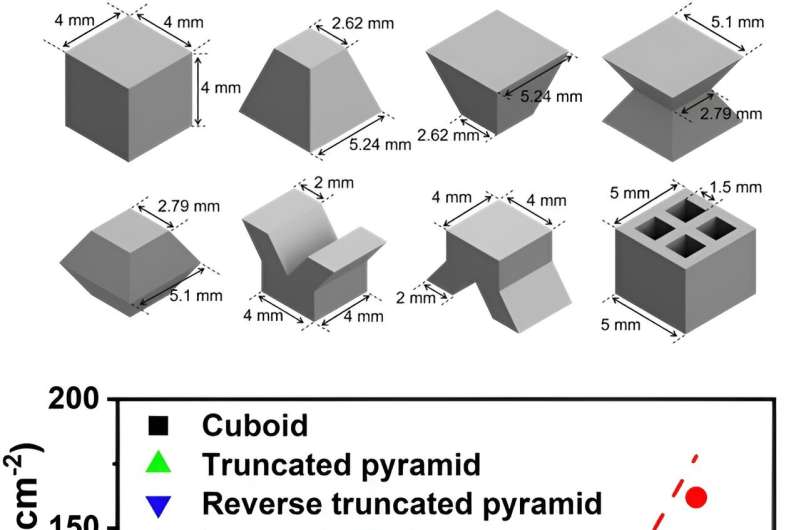

“Traditional thermoelectric devices consist of p- and n-type semiconductor legs, cuboid in shape, arranged in a thermocouple configuration,” Jae Sung Son, co-author of the paper, advised Tech Xplore. “In these units, the design of those legs, when it comes to size and side ratio, is essential for optimizing the thermal and electrical resistances to maximise energy era.

“In this context, non-cuboid three-dimensional (3D) geometries could offer additional level of control over thermal and electrical transport, potentially enhancing device performance beyond what cuboid legs can achieve.”

In 2020, the analysis group led by Prof. Saniya LeBlanc on the George Washington College revealed a paper exploring the leg affect of the semiconductor legs used on the thermoelectric efficiency of thermoelectric energy mills, through a collection of simulations. However the potential of non-cuboid legs had but to be assessed in experimental settings.

“Our group has been working on 3D printing of thermoelectric materials and devices that would allow us to realize the complex geometry of thermoelectric materials that can’t be achieved by traditional manufacturing processes and investigate their impact on power generation performances,” Son defined.

As a part of their examine, Son and his colleagues used 3D finite aspect mannequin simulations to design non-cuboid geometries for the semiconductor legs. They then fabricated these geometric designs utilizing 3D printing strategies and experimentally assessed their efficiency.

“We chose Cu2Se as a model material, due to its high material efficiency at high temperatures,” Son stated. “We carried out numerical simulations on eight totally different geometries, each cuboid and non-cuboids, to judge energy era beneath numerous working circumstances.

“The 3D printing of Cu2Se particle-based colloid inks, tailored by the addition of extra Se82- polyanions enabled us to create the designed geometries of Cu2Se and to comparatively evaluate their power generation performances in a single-leg device.”

The experiments carried out by this group of researchers yielded fascinating outcomes, highlighting the potential of some non-cubic legs over others. Particularly, the group noticed that legs with an hourglass-shaped geometry attained the best energy era, each when it comes to output energy and effectivity.

“This is obviously the first demonstration showing the impact of 3D geometry,” Son stated. “We also found that controlled liquid-phase sintering allowed the defect formation of high-density stacking faults and the resulting dislocations. These defects reduced the thermal conductivity of Cu2Se and consequently enhanced the ZT values up to 2.0.”

The latest examine by Son and his colleagues confirms that the 3D geometry of thermoelectric supplies has a big impression on {the electrical} present they will generate. Whereas they particularly used their technique to design Cu2Se-based supplies, sooner or later it could possibly be utilized to different sorts of thermoelectric supplies, permitting researchers to spice up the efficiency of thermoelectric energy mills with out altering their intrinsic properties.

“In our upcoming studies, we will be applying non-cuboid geometries to different thermoelectric systems, such as segmented devices and Peltier cooling modules,” Son added. “Moreover, integrating structural design tools with thermoelectrics could further enhance device performance and durability.”

Extra info:

Seungjun Choo et al, Geometric design of Cu2Se-based thermoelectric supplies for enhancing energy era, Nature Vitality (2024). DOI: 10.1038/s41560-024-01589-5

© 2024 Science X Community

Quotation:

A method to design higher supplies for thermoelectric energy era (2024, July 29)

retrieved 29 July 2024

from https://techxplore.com/information/2024-07-strategy-materials-thermoelectric-power-generation.html

This doc is topic to copyright. Other than any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.