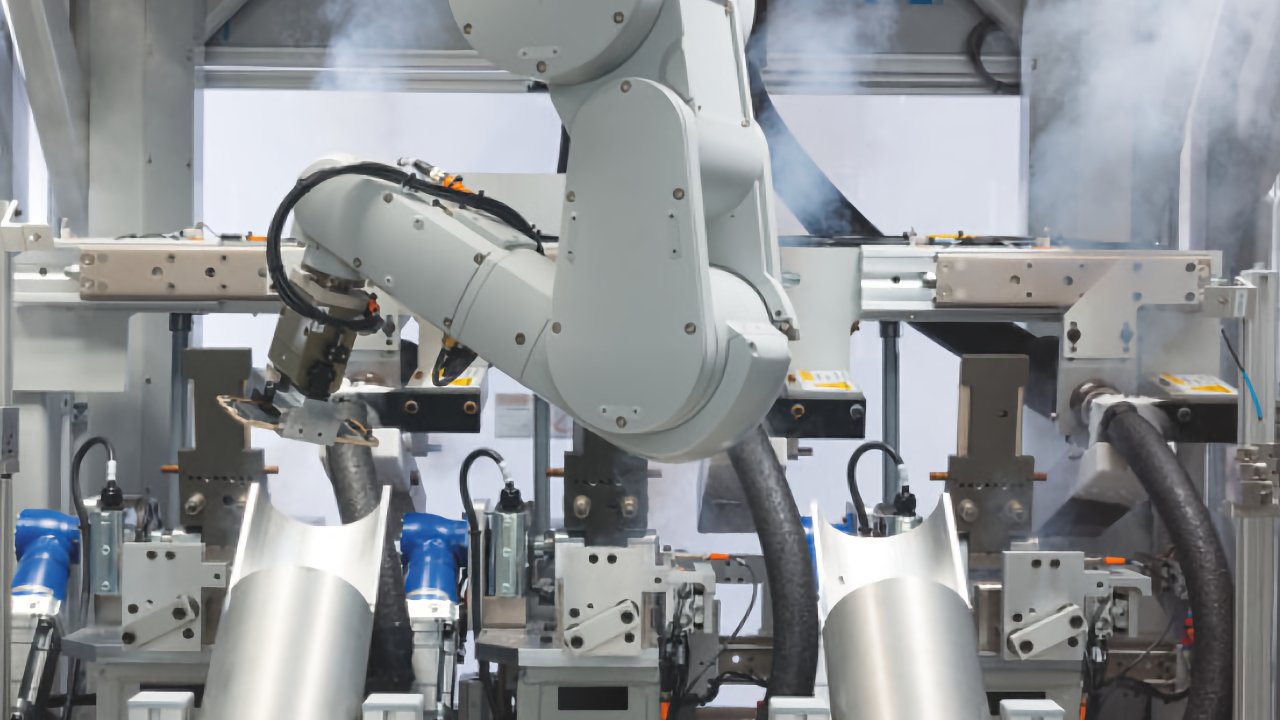

Apple already makes use of robots, like Daisy, in its machine recycling applications

Final up to date

Because of automation, the Cupertino-based tech large plans to cut back the variety of employees assembling the iPhone by as a lot as half, however that might have disastrous results on worldwide labor markets.

Apple has all the time identified that its enterprise was closely reliant on employees in its worldwide factories, equivalent to Foxconn, to make sure the iPhone could be able to ship within the fall.

In 2020, Apple discovered simply how essential they have been. The COVID-19 pandemic precipitated provide chain shortages and delays that the corporate is probably going nonetheless recovering from.

And, it discovered that lesson once more in 2022, when tons of of employees rioted at Foxconn’s primary iPhone manufacturing unit in Zhengzhou, China. Staff alleged that each pay and situations have been abysmal, and movies exhibiting Hazmat-clad law enforcement officials beating the protesters surfaced on social media.

In response to The Info, Apple’s senior vice chairman of operations, Sabih Khan, had despatched an edict telling his managers to “reduce the number of workers on iPhone final assembly lines by as much as 50% over the next few years.”

This meant the corporate would want to resurrect outdated automation tasks it had beforehand postponed because of excessive short-term prices. Nonetheless, the corporate has since closely invested in automation, which allegedly was utilized in producing the iPhone 15.

The push for automation reduces the variety of employees and, due to this fact, may theoretically cut back a few of the value of manufacturing the iPhone — and ultimately different merchandise. Nonetheless, the machines utilized in automation can value tons of of tens of millions of {dollars}, and plenty of of Apple’s manufacturing companions aren’t prepared to make that funding.

Apple’s actual purpose is to keep away from the issues inherent to counting on human employees. In spite of everything, machines do not get sick, do not demand higher situations, and do not require the identical variety of lodging that human employees do.

After all, machines may also be put in and operated in areas that are not in locations that are not actively embattled in US trade-regulation battles, too.

However, in response to the report, there have been some points. Robots used for testing have been having issue inserting small items with sufficient precision, and extra with sufficient screw placement and correct torque.

The affect on China’s labor drive

It’s unclear what that will imply for China’s labor market, which provides tens of millions of employees to Apple’s provide chain. If these employees have been immediately laid off, the results might be disastrous.

Apple’s 2023 provide chain report confirmed that the corporate dropped the variety of staff it screens at manufacturing companions from 1.6 million in 2022 to 1.4 million in 2023. That is a discount of 12.5% in a yr and the primary time that determine shrank in over a decade.

Apple’s automation efforts have been profitable partially because of firms it has acquired alongside the way in which. In early 2024, Apple bought Canadian startup DarwinAI, which The Info factors out can be utilized to examine elements like printed circuit boards for defects.

Apple additionally acquired Drishti, a startup that goals to assist producers determine footage of meeting strains to determine bottlenecks in actual time.

In 2024, Apple deliberate to automate the set up of buttons and different elements on the upcoming iPhone 16. Nonetheless, because of a excessive charge of defects, the corporate has determined to delay its headcount discount targets for an additional yr.