Peter Smith, Sludge Remedy professional at waste administration firm CSG, lifts the lid on the brand new sonar expertise the corporate is utilizing to precisely calculate how a lot sludge or silt is current in a physique of water earlier than removing.

Lagoons, oxidation ditches and settlement ponds are established strategies of clarifying waste waters from a wide range of industries. Gravity settlement is nature’s method of water clarification, however nothing is ideal.

The settled solids don’t simply disappear however merely accumulate on the underside of the lagoon. The issue with that is the settled solids are in a layer and will be unfold over the whole space of the lagoon – and this makes monitoring of the silt accumulation extraordinarily tough.

As sludge accumulates the capability, and subsequently the residence time, inside the lagoon is decreased, which may end up in failures of the discharge consent.

To keep away from this, the lagoon proprietor must understand how a lot silt there’s and the speed at which it’s growing. In the event that they know this, dredging operations will be carried out earlier than the scenario turns into crucial.

That is the place the CSG Sonar Service is invaluable. Initially developed to watch silt construct up in crude oil storage tanks, we now have now tailored the expertise so it may be used on any physique of water.

Weighing simply 25kg and simply deployed by a two-man sonar staff, the Sonar Catamaran maps the floor of the layer of the silt in any lagoon. It’s battery powered with two small generators and is operated remotely from shore.

We are able to use this mapping expertise to permit extra correct estimates of the portions of fabric that may be produced by dredging. The disposal will be the most expensive a part of the mission – typically working into tens and even a whole bunch of hundreds of kilos – and it’s crucial that the consumer has a superb understanding of those prices earlier than getting into right into a contract.

With out sonar expertise, judging the depth of the sludge is a reasonably primitive and inaccurate train, typically involving a protracted dipstick.

A sonar survey will be carried out earlier than and after a dredging mission, so the outcomes are clearly seen to the consumer.

Some purchasers select to watch the silt construct up with a daily survey on an annual foundation. Most surveys will be finished inside the day however, clearly, the bigger the lagoon the longer it takes.

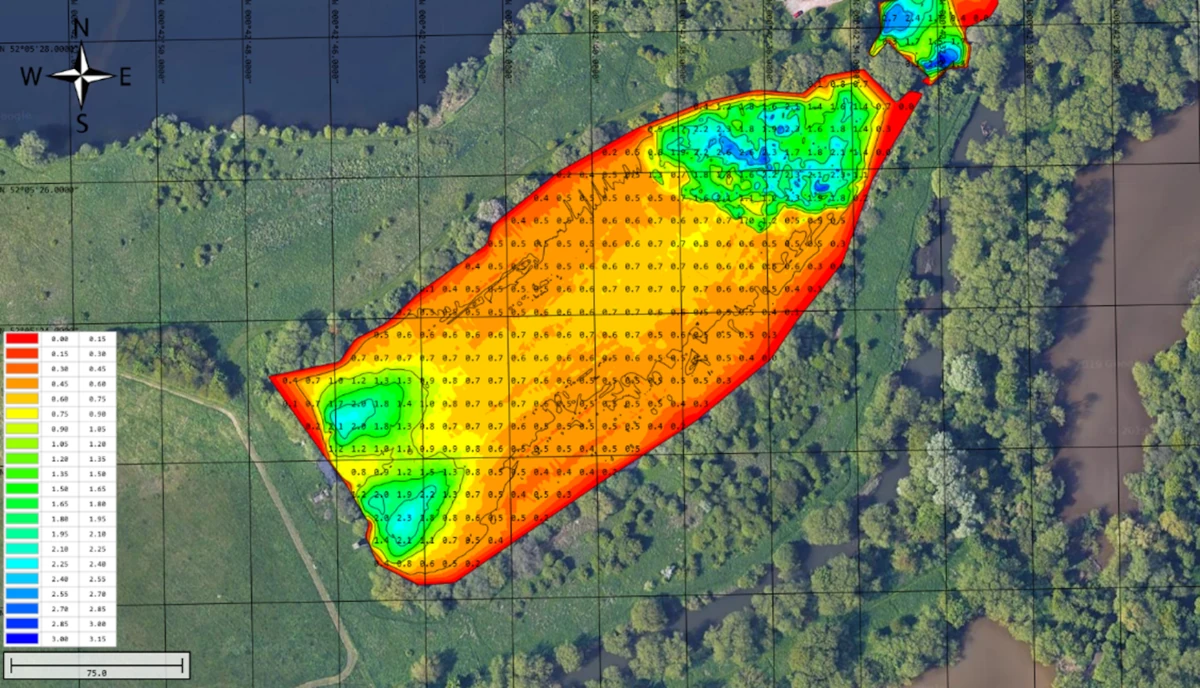

In easy phrases, a sonar survey on a big lagoon will present the depth of fresh water above the sludge and this information is used to provide the 2D picture of the silt floor.

For instance, the utmost depth of the lagoon may be three metres, however in most areas the water may solely be 0.7 metres deep. The issue is clearly demonstrated within the mapping picture and on this case dredging work could be urgently required.

As soon as the quantity of silt to be eliminated is understood, the entire mission is estimated and dredging can start.

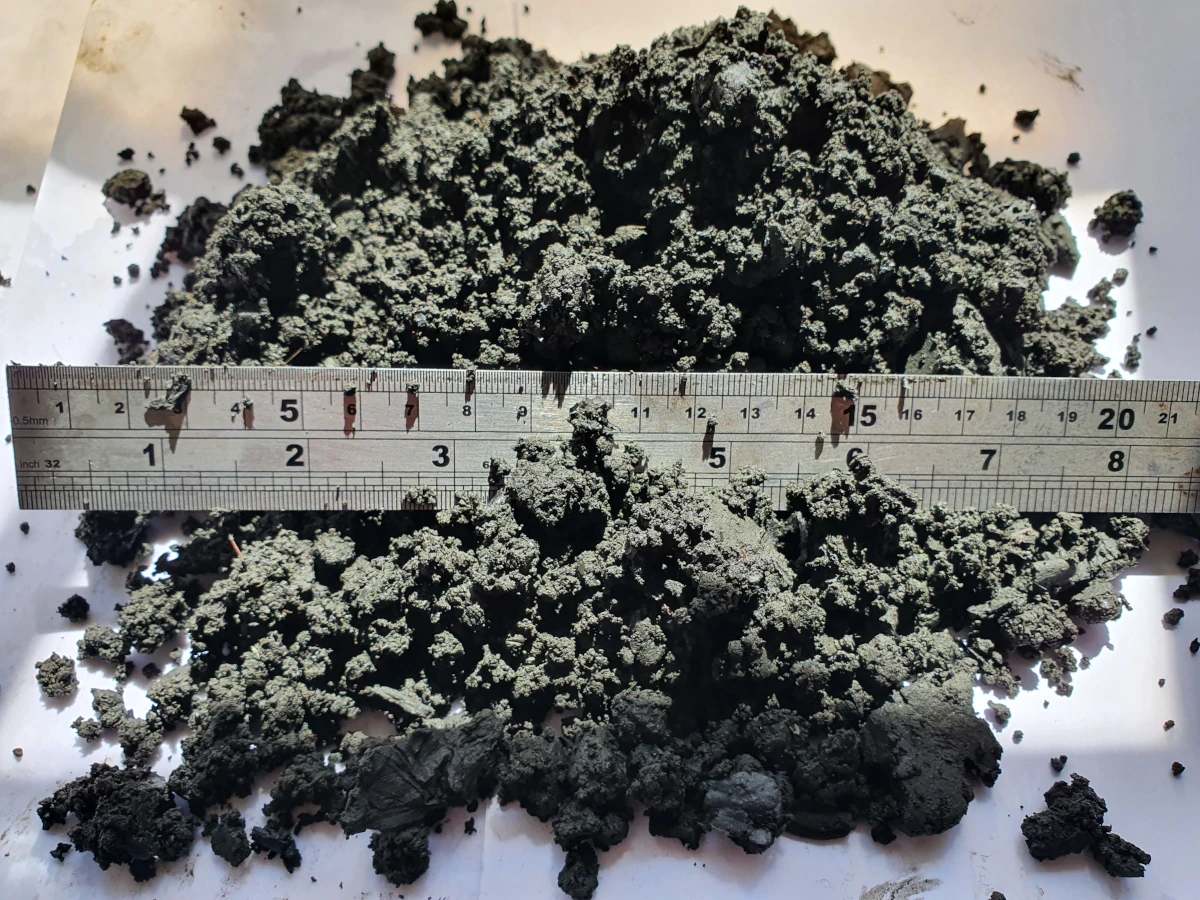

Utilizing a remote-control amphibious dredger, the silt is pumped to shore the place it’s dewatered and turned to a strong cake for removing from web site. The remote-control dredger dramatically will increase security by eliminating people on the water – and reduces prices for the shopper because it removes the necessity for a two-man rescue staff to comply with the dredger.

And by utilizing the sonar gadget beforehand, we have already got an excellent thought of the place the most important build-ups are, bettering effectivity.

A number of strategies are used to dewater the sludge and the positioning circumstances normally dictate essentially the most environment friendly methodology. Not like different suppliers, we use geo luggage, centrifuges or screw press to scale back the water content material of the silt to a degree the place the solids will be transported in bulk tippers.

Geo luggage are giant, permeable cloth containers full of silt and water. They’re used to scale back the water content material of silt by permitting water to empty out by means of the material whereas retaining the strong particles inside. They forestall erosion and minimise contamination – however they will take up appreciable area.

Centrifuges scale back the water content material of silt by quickly spinning the combination in a cylindrical drum, utilising centrifugal power to separate solids from liquids. Because the drum rotates, denser silt particles transfer outward, whereas water is pressured inward and drained away. This course of successfully dewaters silt, producing a drier, extra manageable materials.

Screw presses scale back the water content material of silt by utilizing a rotating screw mechanism inside a cylindrical display. As silt is fed into the press, the screw advances it alongside the display, compressing the fabric and forcing water out by means of the display’s perforations.

We consider the usage of sonar expertise might rework the way in which through which sludge build-up in settlement ponds and lagoons is monitored and maintained. We additionally see makes use of in boating ponds, backwash ponds and ponds for last sprucing. The truth is, we just lately labored on a boating pond which was virtually half silt!

Don’t ignore sludge or silt – converse to the specialists.