Seawater electrolysis holds immense promise as a method to decarbonize the worldwide vitality sector. Nonetheless, challenges similar to anode corrosion by chloride ions, undesirable chloride oxidation reactions, and the excessive value of catalysts have hindered direct seawater electrolysis.

To handle these points, self-supported nickel-iron (NiFe) supplies have emerged as engaging bifunctional catalysts for each hydrogen evolution and oxygen evolution on account of their excessive intrinsic exercise and affordability. Wooden-based carbon (WC) buildings have gained consideration as a perfect substrate for these lively supplies on account of their hierarchical porous nature and wonderful conductivity.

In a bid to boost the steadiness of NiFe-based electrodes in seawater electrolysis, a brand new method was devised by Prof. Hong Chen (Southern College of Science and Expertise in China), Prof. Bing-Jie Ni (College of New South Wales in Australia), and Prof. Zongping Shao (Curtin College in Australia). The analysis is revealed within the journal Science Bulletin.

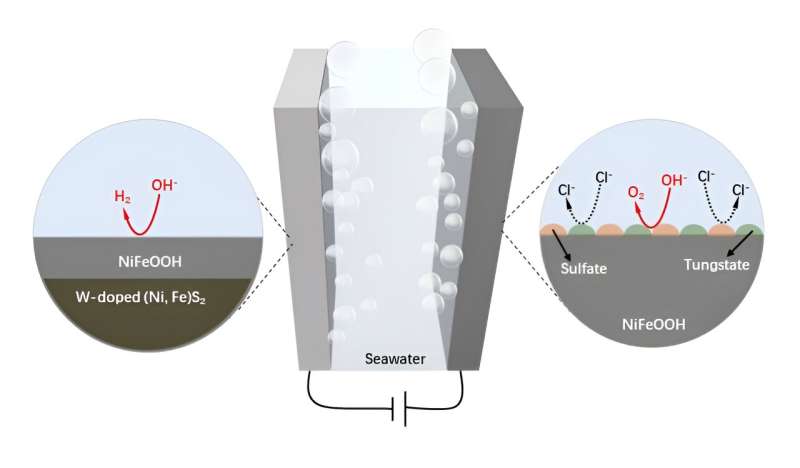

By means of the introduction of tungsten into the lively NiFe-based catalysts, the anti-corrosion properties and stability of the anodes have been considerably improved. The revolutionary WC-supported W-doped NiFe sulfide (W-NiFeS/WC) electrode was developed for environment friendly total seawater electrolysis via a specialised preparation technique involving impregnation and sulfidation.

The crew discovered that the W-NiFeS/WC electrode showcased a three-dimensional hierarchical porous construction with oriented microchannels, densely anchored W-NiFeS nanoparticles, and excessive porosity, bolstering its electrical conductivity and effectivity. The electrode’s efficiency was additional enhanced by its wealthy redox-active facilities, wonderful electrocatalytic properties, and stability in alkaline seawater situations.

The revolutionary electrode demonstrated superior exercise and stability in each the oxygen evolution response (OER) and hydrogen evolution response (HER) in alkaline seawater, outperforming conventional catalysts.

“The in situ structure evolution of W-NiFeS/WC in OER generates anti-corrosive tungstate and sulfate species on the surface of active Ni/Fe oxyhydroxides. Also, the self-evolved W-NiFeS decorated NiFeOOH can catalyze HER efficiently,” says Zhijie Chen, the primary creator. Its low fabrication value and excessive effectiveness make it a compelling alternative for seawater electrolysis, contributing considerably to the development of sustainable hydrogen gas manufacturing.

This analysis not solely underscores the significance of construction reconstruction for vitality conversion reactions, but additionally showcases the potential of wooden waste-derived carbon buildings in superior electrochemical system design. As well as, by repurposing ample wooden waste into environment friendly catalysts for seawater electrolysis, this work embodies a round financial system method, minimizing waste technology, and selling sustainable inexperienced hydrogen manufacturing from seawater.

Extra data:

Zhijie Chen et al, Reconstructed anti-corrosive and lively floor on hierarchically porous carbonized wooden for environment friendly total seawater electrolysis, Science Bulletin (2024). DOI: 10.1016/j.scib.2024.05.044

Science China Press

Quotation:

Innovating sustainable hydrogen manufacturing by way of seawater electrolysis (2024, August 13)

retrieved 13 August 2024

from https://techxplore.com/information/2024-08-sustainable-hydrogen-production-seawater-electrolysis.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.