by KeAi Communications Co.

Lithium-ion batteries are extensively utilized in new vitality automobiles because of their low self-discharge charge and lengthy cycle life. At the moment, the anode materials of business lithium-ion batteries primarily adopts graphite, with a theoretical capability of solely 372 mAh g-1—which has regularly failed to satisfy the rising demand for vitality density.

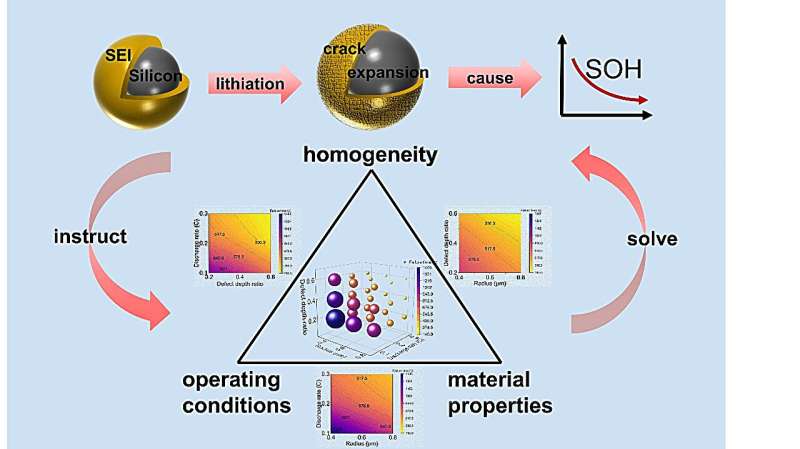

Silicon has been extensively studied by advantage of its excessive theoretical capability of 4,200 mAh g-1. Nevertheless, silicon produces quantity adjustments of as much as 300% throughout lithiation and delithiation, and the following mechanical degradation and capability loss hinder purposes.

To scale back the adversarial results brought on by mechanical deformation, silicon construction optimization has been intensively investigated and has successfully improved the biking efficiency. Nonetheless, the long-term growth of silicon-based vitality storage supplies requires not solely secure electrodes, but additionally a secure interphase between electrodes and electrolytes.

Natural electrolytes, that are extensively utilized in standard lithium-ion batteries, scale back on the anode floor to kind a skinny movie referred to as stable electrolyte interphase (SEI).

Sadly, drastic quantity adjustments in silicon can result in the buildup of stress and destruction of the SEI, which is able to subsequently regenerate on the uncovered anode floor, tremendously rising irreversible lithium and electrolyte consumption and inflicting capability degradation. Due to this fact, it’s significantly necessary to stabilize the mechanical properties of SEI on silicon supplies.

To that finish, the Superior Energy Analysis Group led by Peng Tan of the College of Science and Expertise of China (USTC) has initiated a modeling research on the mechanical stability of SEI from three views: electrode materials properties, SEI geometrical properties, and battery working circumstances. The work has been revealed in Superior Powder Supplies.

The modeling was primarily based on the continuum mechanics mannequin, coupled with the electrochemical mass switch course of.

The workforce quantitatively analyzed the consequences of three components on SEI stability and battery capability utilization by constructing a mannequin of particular person electrode particles.

They discovered that as a way to enhance SEI stability, spherical silicons with smaller particle sizes ought to be used as a lot as potential within the design of electrode supplies. By way of SEI geometry, it’s significantly necessary to artificially assemble SEI with a uniform construction, whereas in the case of cell operation, excessive multiplicity will deliver larger capability utilization however is just not conducive to SEI stability.

The findings exhibit SEI’s high-stability design and operation technique and can information the event of silicon-based vitality storage batteries with excessive biking stability.

Extra info:

Junjie Ding et al, Investigating the failure mechanism of stable electrolyte interphase in silicon particles from an electrochemical-mechanical coupling perspective, Superior Powder Supplies (2024). DOI: 10.1016/j.apmate.2024.100200

Supplied by

KeAi Communications Co.

Quotation:

Investigating failure mechanisms of stable electrolyte interphase in silicon particles (2024, Could 22)

retrieved 26 Could 2024

from https://techxplore.com/information/2024-05-failure-mechanisms-solid-electrolyte-interphase.html

This doc is topic to copyright. Other than any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.