Researchers on the College of Maryland genetically modified poplar bushes to supply high-performance, structural wooden with out the usage of chemical substances or energy-intensive processing. Created from conventional wooden, engineered wooden is commonly seen as a renewable alternative for conventional constructing supplies like metal, cement, glass and plastic. It additionally has the potential to retailer carbon for an extended time than conventional wooden as a result of it may resist deterioration, making it helpful in efforts to scale back carbon emissions.

However the hurdle to true sustainability in engineered wooden is that it requires processing with risky chemical substances and a big quantity of power, and produces appreciable waste. The researchers edited one gene in reside poplar bushes, which then grew wooden prepared for engineering with out processing.

The analysis was printed on-line on August 12, 2024, within the Journal Matter.

“We are very excited to demonstrate an innovative approach that combines genetic engineering and wood engineering, to sustainably sequester and store carbon in a resilient super wood form,” stated Yiping Qi, a professor within the Division of Plant Science and Panorama Structure at UMD and a corresponding writer of the research. “Carbon sequestration is critical in our fight against climate change, and such engineered wood may find many uses in the future bioeconomy.”

Earlier than wooden may be handled to impart structural properties similar to elevated energy or UV resistance, which permits it to be substituted for metal or concrete, it have to be stripped of certainly one of its predominant elements, known as lignin.

Beforehand, UMD researchers efficiently developed strategies for eradicating lignin utilizing numerous chemical substances, and others have explored the usage of enzymes and microwave know-how. With this new analysis, Qi and his colleagues sought to develop a technique that doesn’t depend on chemical substances, produce chemical wastes or depend on giant quantities of power.

Utilizing a know-how known as base enhancing to knock out a key gene known as 4CL1, the researchers have been in a position to develop poplars with 12.8% decrease lignin content material than wild-type poplar bushes. That is akin to the chemical therapies utilized in processing engineered wooden merchandise.

Qi and his collaborators grew their knock-out bushes aspect by aspect with unmodified bushes in a greenhouse for six months. They noticed no distinction in development charges and no vital variations in construction between the modified and unmodified bushes.

To check the viability of their genetically modified poplar, the workforce, led by professor of supplies science and engineering, Liangbing Hu, used it to supply small samples of high-strength compressed wooden just like particle board, which is commonly utilized in constructing furnishings.

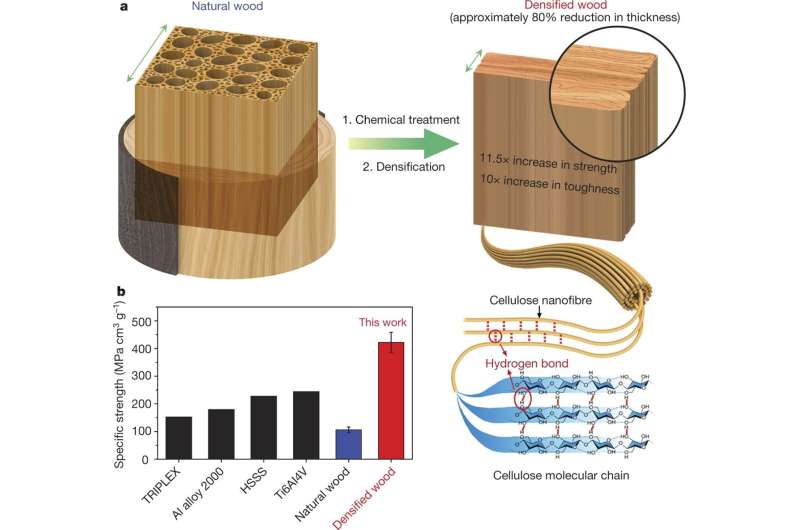

Compressed wooden is made by soaking wooden in water beneath a vacuum after which hot-pressing it till it’s practically 1/5 of its authentic thickness. The method will increase the density of the wooden fibers. In pure wooden, lignin helps cells preserve their construction, and prevents them from being compressed. The decrease lignin content material of chemically handled or genetically modified wooden permits the cells to compress to a better density, rising the energy of the ultimate product.

To judge the efficiency of their genetically edited bushes, the workforce additionally produced compressed wooden from the pure poplar, utilizing untreated wooden and wooden that they handled with the standard chemical course of to scale back the lignin content material.

They discovered that the compressed genetically modified poplar carried out on a par with the chemically processed pure wooden. Each have been denser and greater than 1.5 instances stronger than compressed, untreated, pure wooden.

The compressed genetically modified wooden had a tensile energy akin to aluminum alloy 6061 and the compressed wooden that had been chemically handled.

This work opens the door to producing quite a lot of constructing merchandise in a comparatively low-cost, environmentally sustainable method at a scale that may play an vital function within the battle in opposition to local weather change.

Extra data:

Genome-Edited Bushes for Excessive-Efficiency Engineered Wooden, Matter (2024). DOI: 10.1016/j.matt.2024.07.003. www.cell.com/matter/fulltext/S2590-2385(24)00396-5

College of Maryland

Quotation:

New genetically engineered wooden can retailer carbon and scale back emissions (2024, August 12)

retrieved 12 August 2024

from https://techxplore.com/information/2024-08-genetically-wood-carbon-emissions.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.