Layers of carbon atoms in a honeycomb array are a real supermaterial: their unusually excessive conductivity and favorable mechanical properties may additional the event of bendable electronics, new batteries, and modern composite supplies for aeronautics and house flight. Nonetheless, the event of elastic and hard movies stays a problem.

Within the journal Angewandte Chemie, a analysis crew has now launched a way to beat this hurdle: they linked graphene nanolayers through “extendable” bridging buildings.

The particular capabilities of microscopic graphene nanolayers typically drop off when the layers are assembled into foils, as a result of they’re solely held collectively by comparatively weak interactions—primarily hydrogen bonds.

Approaches that try to enhance the mechanical properties of graphene foils by introducing stronger interactions have solely been partially profitable, leaving specific room for enchancment within the stretchability and toughness of the supplies.

A crew led by Xuzhou Yan at Shanghai Jiao Tong College (China) took a brand new method: they cross-linked graphene nanolayers with mechanically interlocked molecules whose constructing blocks aren’t chemically linked, however moderately inseparably spatially entangled. The researchers selected to make use of rotaxanes as their hyperlinks.

A rotaxane is a “wheel” (a big ring-shaped molecule) that’s “threaded” onto an “axle” (a molecular chain). Cumbersome teams cap the axles to forestall the wheels from coming unthreaded. The crew constructed their axle with a charged group (ammonium) that holds the wheel in a selected place.

A molecular “anchor” (OH group) was connected to each the axle and wheel by a linker. The graphene was oxidized to make graphene oxide, which types a wide range of oxygen-containing teams on each side of the graphene layer. These embrace carboxyl teams, which might bind to the OH teams (esterification). This response permits the wheel and axle to cross-link the layers, after which the graphene oxide is decreased again to graphene.

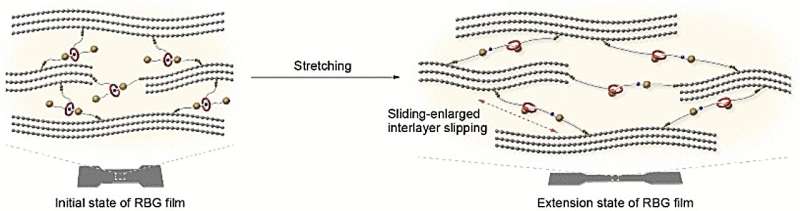

When these movies are stretched or bent, the engaging forces between the wheel and the ammonium group on the axle should be overcome, which will increase the tensile power. Elevated stress finally causes the axle to be pulled by means of the wheel till it “strikes” the top cap. This movement lengthens the rotaxane-bridges, permitting the layers to slip throughout one another, which considerably will increase the stretchability of the movie.

Versatile electrodes produced from this graphene-rotaxane foil could possibly be stretched as much as 20% or bent repeatedly with out being broken. Additionally they retained their excessive electrical conductivity. Solely stretching by over 23% led to fracture.

The brand new foils have been significantly stronger than foils with out rotaxanes (247.3 vs. 74.8 MPa), in addition to extra elastic (23.6 vs. 10.2%), and harder (23.9 vs. 4.0 MJ/m3). The crew additionally constructed a easy “grasping tool” with mechanical joints that have been outfitted with and actuated by the brand new foils.

Extra data:

Chunyu Wang et al, A Stretchable and Robust Graphene Movie Enabled by Mechanical Bond, Angewandte Chemie Worldwide Version (2024). DOI: 10.1002/anie.202404481

Quotation:

New technique hyperlinks graphene nanolayers for harder, elastic movies (2024, June 14)

retrieved 14 June 2024

from https://phys.org/information/2024-06-method-links-graphene-nanolayers-tougher.html

This doc is topic to copyright. Other than any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.