This text incorporates paid for content material produced in collaboration with T-T Stream.

Authorities-backed funding noticed a Stockport website grow to be the primary within the UK to be retrofitted with an modern new expertise that reinforces biogas manufacturing by as much as 20%. Valves play a crucial position in its deployment.

The Stockport Sludge Therapy Centre in Better Manchester processes over 600 m3 of sludge from native wastewater remedy services each day. Anaerobic digestion (AD) transforms the sludge into biogas that’s used to supply electrical energy to energy greater than 1200 houses p.a.

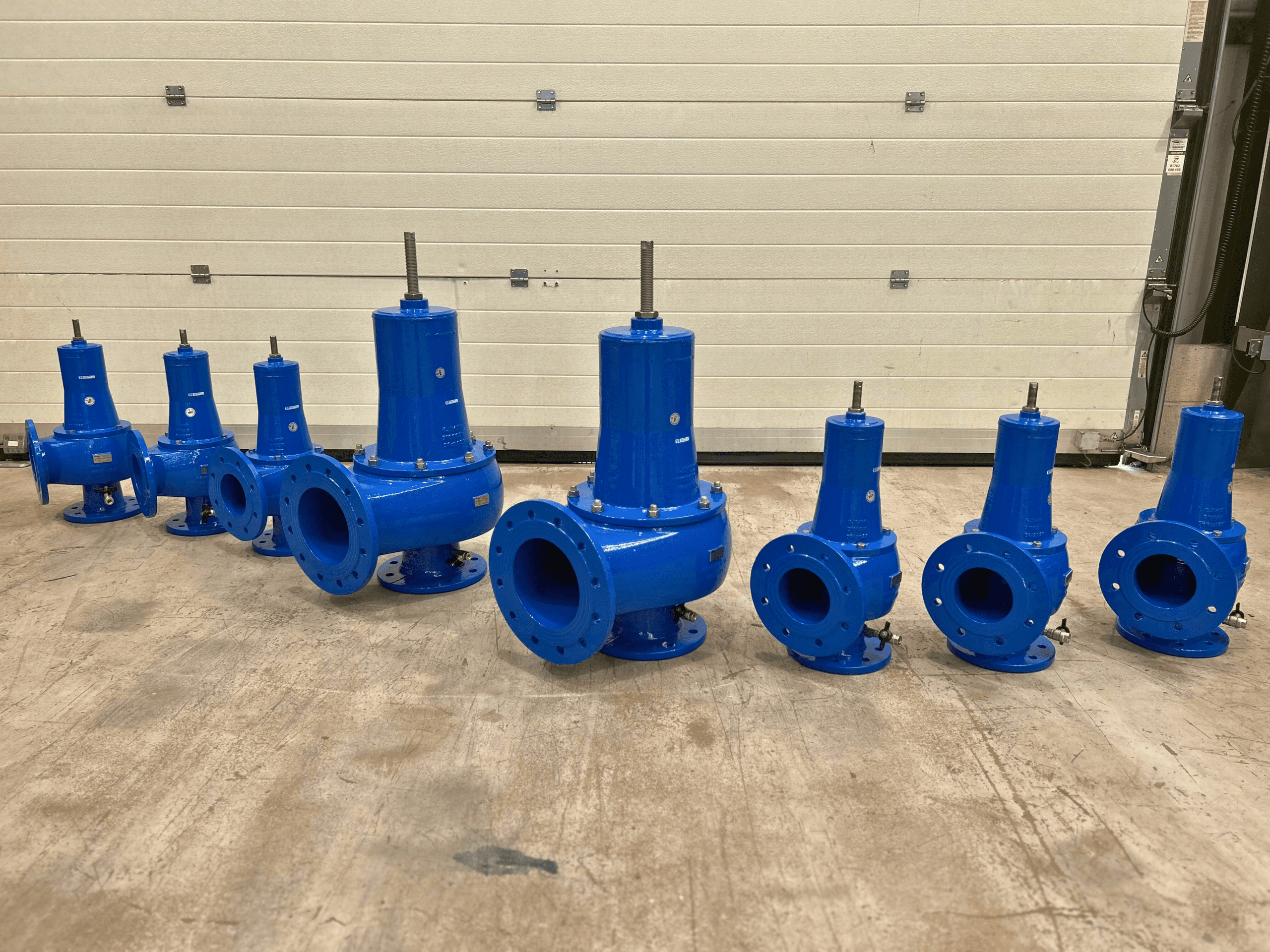

As a part of the retrofit, T-T Stream had been requested to supply an entire valve bundle, together with knife-gate valves, swing-check valves and fast-acting reduction valves.

The equipped reduction valves are set to play a vital position in on-site security. Given the stress produced by the system’s AD processes, the necessity is all of the better to reduce the probability of surge occasions like water hammer occurring. Stream inefficiencies, harm to infrastructure and explosions are all potential penalties of not successfully managing system stress. The self-acting reduction valves mitigate the danger. Calibrated to take care of the specified stress, they function by opening when this stress is exceeded and discharge extra fluid to keep away from an over-pressure occasion.

T-T Stream have specified reduction valves that reply shortly and reliably to stress fluctuations, that includes fast-acting annealed springs and a clean, light-weight inside profile that minimises operational resistance. To ensure long-term operational reliability throughout the corrosive atmosphere of the sludge remedy facility, the chosen valves are comprised of a high-strength/low-weight ductile iron physique, a precision machined chrome steel seat, and A2-70 chrome steel fasteners.

ttpumps.com/merchandise/valves