By James Kennedy, a know-how analyst at market intelligence agency IDTechEx.

The superior recycling marketplace for plastics predominantly focuses on applied sciences like pyrolysis and depolymerization (thermal, chemical, and enzymatic). To a lesser extent, strategies reminiscent of gasification and hydrothermal liquefaction are additionally being explored. Nonetheless, these applied sciences face growing scrutiny and restrictions in some areas because of their environmental influence. Nonetheless, whereas mechanical recycling is the popular recycling technique because of its cost-effectiveness and effectivity, it nonetheless falls brief in purposes requiring excessive purity and mechanical properties. To deal with these challenges posed by each chemical recycling applied sciences and mechanical recycling, dissolution applied sciences (generally known as solvent extraction) supply a promising resolution.

Dissolution defined

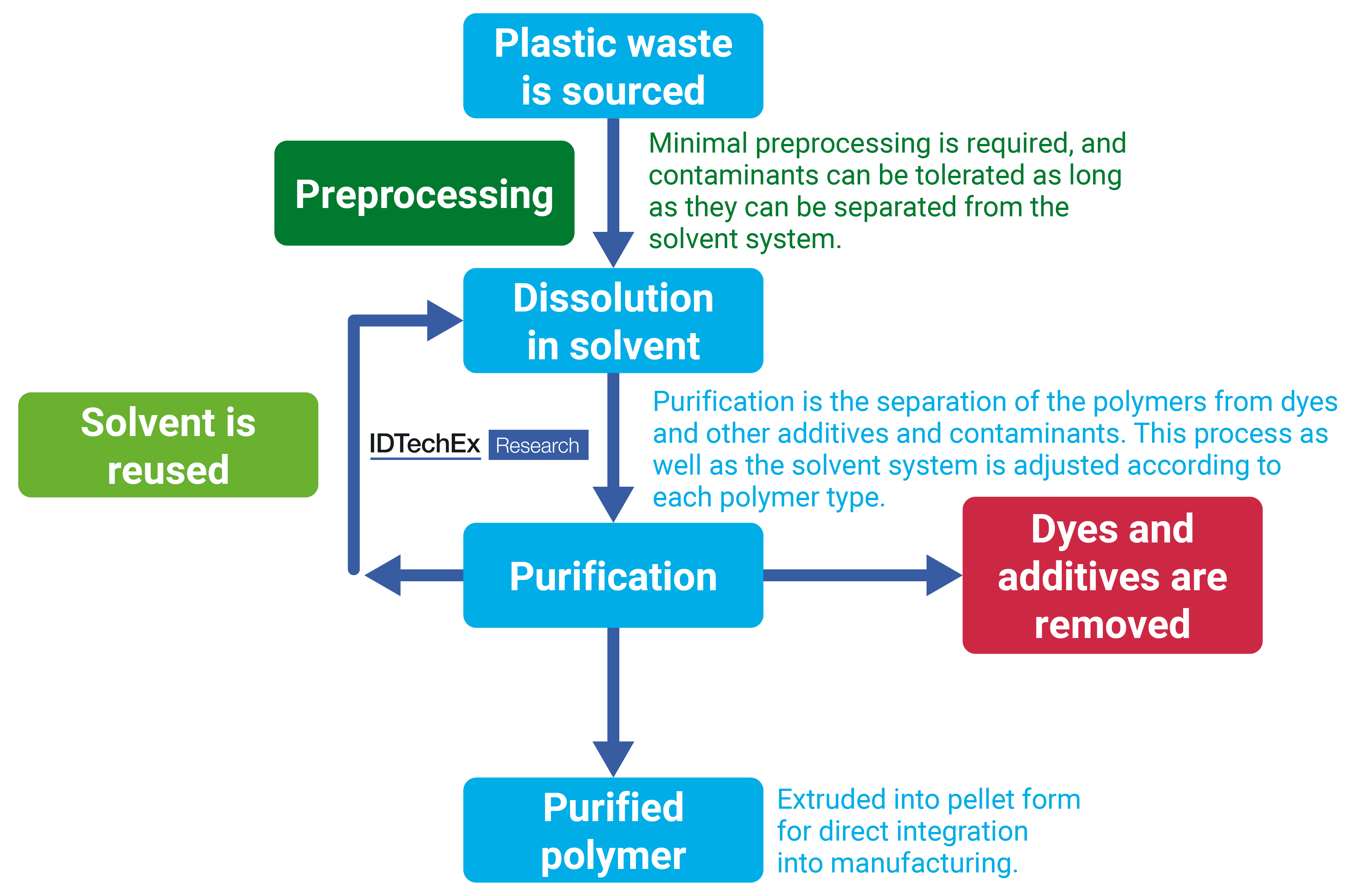

Dissolution includes separating polymer waste utilizing a solvent. The solvent selectively dissolves the polymer, separating it from contaminants and different non-target supplies. As soon as dissolved, the answer is purified, and the solvent is eliminated, forsaking a virtually pure plastic that may be processed again into granules for reuse in manufacturing.

This technique can take care of contaminated or blended plastic waste that’s difficult to recycle by way of mechanical means whereas not breaking the polymers into their constituent molecules or feedstock. The necessity to fastidiously separate completely different polymer varieties is lowered, as plastic varieties might be selectively dissolved and separated out when utilizing the right solvent combination. The processes are designed with solvents and separation strategies for particular plastic varieties reminiscent of polypropylene, polystyrene, and acrylonitrile butadiene styrene.

PureCycle Applied sciences is a notable participant within the area of plastic dissolution. The corporate makes use of a proprietary know-how developed by Procter & Gamble to recycle polypropylene. Its course of includes utilizing a solvent (primarily n-butane) to purify waste polypropylene right into a type that’s comparable in high quality to virgin plastic. PureCycle states that its recycled PP can be utilized in purposes the place mechanical recycling strategies, reminiscent of food-grade packaging, wouldn’t suffice. PureCycle is at present the main commercial-scale supplier on this area.

The important thing benefit of dissolution is the upper theoretical general yield that it may possibly present in comparison with chemical recycling applied sciences, because the product re-enters the plastic provide chain as a ready-for-use resin fairly than merely a polymer constructing block or a hydrocarbon.

As a comparatively nascent business, there’s persevering with R&D on its processes. One standout is Solvent-Focused Restoration and Precipitation (STRAP), which is a brand new know-how framework that researchers on the College of Wisconsin-Madison have developed. The know-how can separate the elements of multilayer plastic movies and take away contaminants. Multilayer movies are a key problem in plastic waste administration, and because of this, the commercialization of this know-how has sturdy potential. Moreover, the builders of STRAP declare the method has many benefits over rivals, together with operation at atmospheric stress and decrease temperatures. At current, a STRAP pilot plant is being constructed at Michigan Tech College to show the know-how. The promise of a extremely adaptable dissolution system for this sort of hard-to-recycle plastic waste can be probably the most sought-after resolution. The technical challenges of scaling STRAP will possible imply a number of years earlier than that is at a industrial scale.

The overall course of for the dissolution of plastic waste (supply: IDTechX). Click on picture to enlarge.

Dissolution drawbacks

Whereas dissolution know-how holds promise, it isn’t with out its challenges and criticisms. For instance, there are questions on long-term circularity because the polymer is prone to degrade over successive biking. One other concern with the dissolution course of is the environmental influence of the solvents used. These chemical substances should be managed fastidiously to keep away from releasing dangerous substances into the atmosphere. The vitality required to warmth the solvents and subsequently take away them from the dissolved plastic additionally provides to the carbon footprint of the method.

The financial viability of dissolution know-how additionally stays unsure. The price of the solvents, vitality consumption, and the necessity for classy infrastructure will possible make recycled polymers from dissolution vegetation dearer than with mechanical recycling strategies. The dimensions of this inexperienced premium versus different recycling applied sciences will decide whether or not dissolution vegetation might be economically viable.

Moreover, the dimensions required to make a big influence on plastic waste by way of dissolution is immense. Constructing the required infrastructure to course of massive volumes of plastic waste by way of dissolution is an enormous enterprise that can require substantial capital funding and time.

The success of dissolution applied sciences like PureCycle’s is determined by market demand for recycled plastics. Whereas there’s rising curiosity in sustainable supplies, competitors from cheaper, virgin plastics can restrict the market potential for recycled merchandise. Future efforts will concentrate on growing processes for a wider vary of polymer varieties. Corporations reminiscent of APK, Worn Once more, and Polystyvert are working with polyethylene (PE), polyethylene terephthalate (PET), and polystyrene (PS), respectively. The Netherlands Group for Utilized Scientific Analysis (TNO) is growing a course of known as Mobius for recycling acrylonitrile butadiene styrene (ABS), although it isn’t but commercialized.

Dissolution presents a promising know-how for addressing the demand for low-carbon, versatile plastic waste options. Nonetheless, a number of hurdles stay, together with technological refinement, industrial scaling, and financial challenges. Stakeholders should fastidiously consider the advantages and disadvantages of dissolution throughout the broader context of world waste administration methods. Navigating financial challenges will probably be key, as worth would be the determinant consider success as corporations adopting recycled polymers consider how a lot of a inexperienced premium they’ll afford. Continued analysis, funding, and regulatory help will probably be important to refine the method and assess its long-term viability as a part of a complete effort to mitigate the influence of plastic waste on the atmosphere.